The drill rigs kept breaking down. No warning, just sudden failures that would halt production and send costs soaring. Mufaro Handirimi had seen enough to know the mining industry had a problem it wasn't solving.

The 22-year-old Zimbabwean innovator decided to try and do something about it, using the power of real-time predictive intelligence.

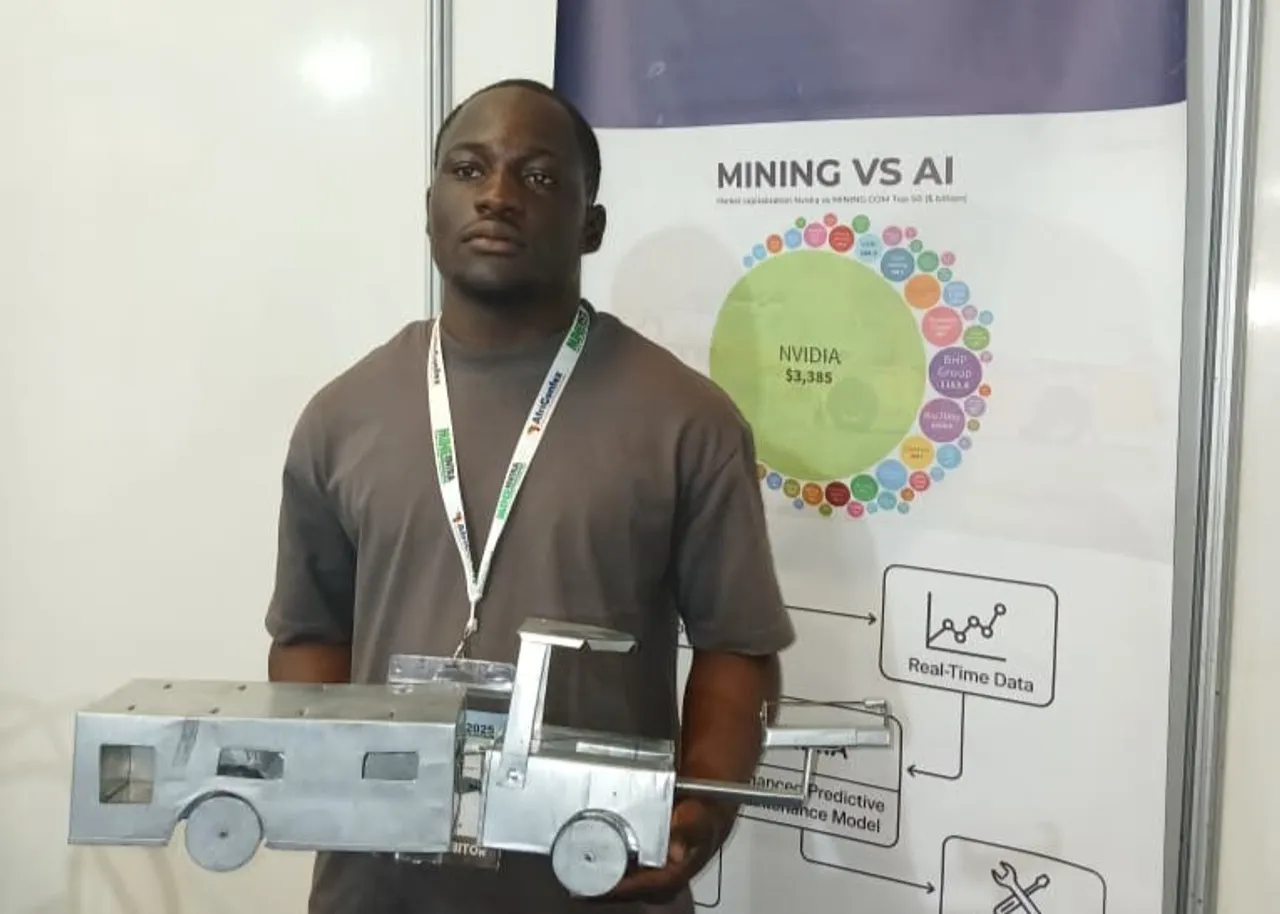

Handirimi, a 2025-batch mining engineering graduate from Midlands State University in Gweru, heads entrepreneurship at the Association of Junior Mining Professionals of Zimbabwe and has developed Drill Sense Pro, a platform that uses real-time data analysis to forecast when drilling equipment will fail.

Statistics reflect the scale of the problem. Mining equipment typically runs at just 80% availability, according to research published in the Journal of Quality in Maintenance Engineering. That means one-fifth of operational time is lost to maintenance and breakdowns.

Traditional maintenance teams rely on human observation alone, without computational support. As a result, they miss early-stage faults that could be caught and fixed before equipment fails completely.

The financial implications of breakdowns make it worse. Research published in the Engineering & Mining Africa magazine shows these inefficiencies can drain between $20,000 and $250,000 per rig every month.

Zimbabwe's mining companies have publicly acknowledged the impact. One operator recently reported a 7% year-on-year drop in mined volumes, partly attributed to poor availability of mobile underground machinery.

Predicting breakdowns

Handirimi believes the most practical solution lies in letting machines analyse themselves.

"In underground platinum mining, the cycle begins with drilling, then blasting and hauling. Productivity depends heavily on drilling," he explains. "The underground drill rig is central to this process. When it goes down, costs rise and productivity collapses."

Drill Sense Pro is built specifically for underground drill rigs used in platinum mining. Rather than waiting for equipment to break, the system analyses machine behaviour as it happens, looking for patterns that signal approaching failure.

Currently, the platform is tailored for the Sandvik DD211 low-profile drill rig, concentrating on the hydraulic and drill modules where most catastrophic failures are known to occur.

Self-learning intelligence

At its core, the system works as a continuous feedback loop. "In simple terms, Drill Sense Pro learns from itself," Handirimi tells TRT Afrika. "This enhances its ability to think critically in unforeseen scenarios."

By using real-time data to forecast maintenance needs, the platform aims to shift the industry away from accepting downtime as inevitable.

"In many mines, breakdowns are often accepted as normal, but they shouldn't be," says Handirimi. "The root of the problem is the lack of real-time machine intelligence. If we can predict failures before they happen, we save costs, extend component life and increase production safely."

The safety implications are significant too. Unscheduled breakdowns can force personnel into extended working hours under production pressure, which compromises safety. Handirimi believes his system helps address this risk.

Building the platform

Developing Drill Sense Pro took around eight months of intensive work, much of it spent creating structure from inconsistent data and limited digital infrastructure.

"One of the biggest challenges was creating order out of chaos," recalls Handirimi. "I worked with inconsistent data and limited digital infrastructure. Instead of complaining, I treated every obstacle as a training ground, which forced me to think harder and design a system that works in tough environments."

Handirimi's mission is far from complete. "Innovation is a living process," he tells TRT Afrika. "We keep improving, optimising and sharpening the system as new insights come."

Having established the digital foundation, Handirimi plans to develop an industrial-size sensor built on the same intelligence that powers Drill Sense Pro.

He hopes this will transform the platform from software into a fully integrated physical mining solution, putting predictive intelligence at the heart of mining operations.