Drill rigs dey always spoil. No warning, e go just kpai, shut production down and make cost climb high. Mufaro Handirimi don see enough to know say the mining industry get wahala wey dem need to solve.

Di 22-year-old Zimbabwean innovator decide to do sometin about am, using the power of real-time predictive intelligence.

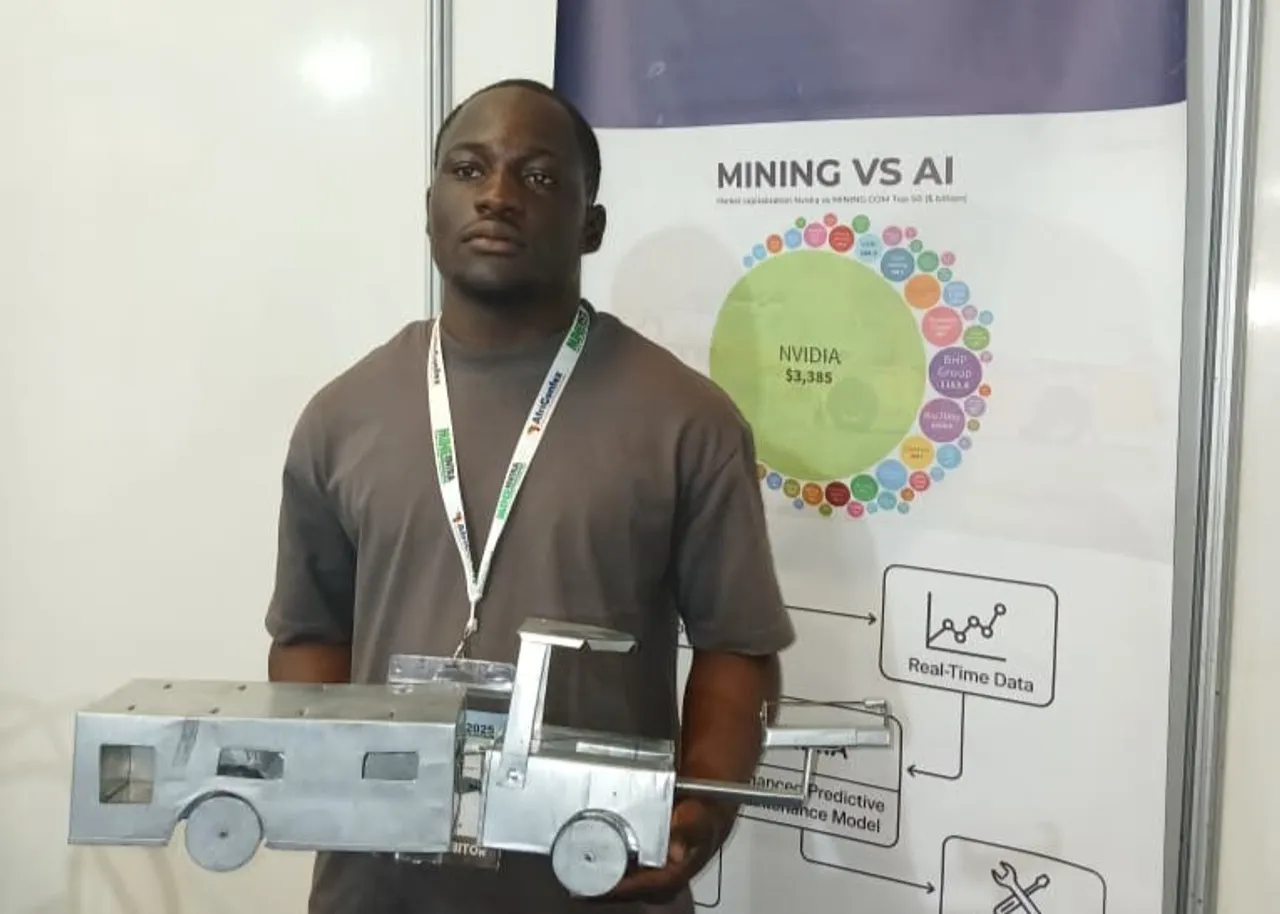

Handirimi, na 2025-batch mining engineering graduate from Midlands State University for Gweru, dey head entrepreneurship for the Association of Junior Mining Professionals of Zimbabwe. E don develop Drill Sense Pro, platform wey dey use real-time data analysis to forecast when drilling equipment go fail.

Statistics show how big the problem be.

Research wey publish for the Journal of Quality in Maintenance Engineering talk say mining equipment dey run only about 80% availability. That one mean say one-fifth of operational time dey lost to maintenance and breakdowns.

Traditional maintenance teams dey rely on human observation alone, without computer support. As result, dem dey miss early-stage faults wey dem fit catch and fix before equipment spoil completely.

The financial side make am worse. Research wey publish for Engineering & Mining Africa magazine show say these inefficiencies fit drain between $20,000 and $250,000 per rig every month.

Zimbabwe mining companies don publicly admit the impact. One operator recently report say mined volumes drop 7% year-on-year, part because mobile underground machinery no dey available well.

How dem dey predict breakdowns

Handirimi believe say the most practical solution na to make machines analyse themselves.

"For underground platinum mining, the cycle dey begin with drilling, then blasting and hauling. Productivity depend well on drilling," e explain. "The underground drill rig be central to this process. When e go down, cost rise and productivity collapse."

Drill Sense Pro build specially for underground drill rigs wey dem use for platinum mining. Instead of to dey wait make equipment spoil, the system dey analyse machine behaviour as e dey happen, dey look for patterns wey show say failure dey come.

At the moment, the platform dey tailored for the Sandvik DD211 low-profile drill rig, focusing on the hydraulic and drill modules where most serious failures dey occur.

Machine wey dey learn by itself

For the core, the system dey work as continuous feedback loop. "For simple terms, Drill Sense Pro dey learn from itself," Handirimi tell TRT Afrika. "This dey improve im ability to reason for unforeseen scenarios."

By using real-time data to forecast maintenance needs, the platform dey try shift the industry away from accepting downtime as something wey must happen.

"For plenty mines, dem dey accept breakdowns as normal, but dem no suppose," Handirimi talk. "Root of the problem na lack of real-time machine intelligence. If we fit predict failures before dem happen, we go save cost, make components last longer and increase production in a safe way."

Safety matter big too. Unscheduled breakdowns fit force workers to work extra hours because production pressure, and that one fit compromise safety. Handirimi believe say him system fit help reduce this risk.

How e build the platform

To develop Drill Sense Pro e take about eight months of intensive work, most of the time na to create structure from inconsistent data and limited digital infrastructure.

"One of the biggest challenges na to create order out of chaos," Handirimi recall. "I work with inconsistent data and limited digital infrastructure. Instead of to dey complain, I treat every obstacle as training ground, and that force me to think harder and design system wey fit work for tough environments."

Handirimi mission never finish. "Innovation na living process," e tell TRT Afrika. "We go dey improve, optimise and sharpen the system as new insights come."

After e don establish the digital foundation, Handirimi plan to develop industrial-size sensor wey go use the same intelligence wey dey power Drill Sense Pro.

E hope say this go transform the platform from software into fully integrated physical mining solution, put predictive intelligence for the heart of mining operations.